CMRL achieves second Tunnel Breakthrough at Thirumayilai for Chennai Metro Phase 2 Corridor 4

CMRL achieves second Tunnel Breakthrough at Thirumayilai for Chennai Metro Phase 2 Corridor 4 NHSRCL invites Single Tender from BEML for Bullet Train Rolling Stock Package

NHSRCL invites Single Tender from BEML for Bullet Train Rolling Stock Package Railway Minister reviews progress of Ahmedabad–Dholera Semi High-Speed Rail Project

Railway Minister reviews progress of Ahmedabad–Dholera Semi High-Speed Rail Project National Planning Group reviews key Rail & Metro projects under PM GatiShakti

National Planning Group reviews key Rail & Metro projects under PM GatiShakti CMRS approves Driverless Metro Operations on first stretch of Chennai Metro Phase 2 Corridor 4

CMRS approves Driverless Metro Operations on first stretch of Chennai Metro Phase 2 Corridor 4 J Kumar Infraprojects completes Final Tunnel Breakthrough for Surat Metro Phase 1 Project

J Kumar Infraprojects completes Final Tunnel Breakthrough for Surat Metro Phase 1 Project Apurvakriti Infrastructure awarded Ballastless Track Contract for Pune Metro Reach-1 Extension

Apurvakriti Infrastructure awarded Ballastless Track Contract for Pune Metro Reach-1 Extension SAM India Builtwell bags first ₹222.76 Crore Civil Contract for Delhi Metro Phase V

SAM India Builtwell bags first ₹222.76 Crore Civil Contract for Delhi Metro Phase V HRIDC conducts Investors Pre-Bid Meeting for Haryana Orbital Rail Corridor

HRIDC conducts Investors Pre-Bid Meeting for Haryana Orbital Rail Corridor NCRTC Chief Shalabh Goel appointed as General Manager of Central Railway

NCRTC Chief Shalabh Goel appointed as General Manager of Central Railway

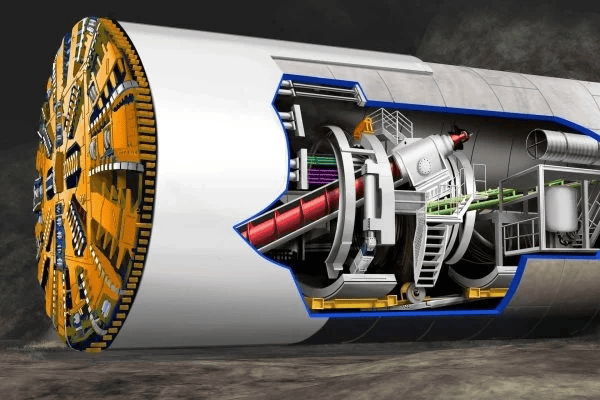

Herrenknecht to establish India's Largest TBM Manufacturing Facility in Chennai

The total investment for this expansion is planned to be approximately Rs250 crore

Chennai, India (Metro Rail Today): German tunneling technology leader, Herrenknecht AG, is significantly boosting India's infrastructure drive by expanding its presence in Chennai, Tamil Nadu, with what is planned to be the nation's largest Tunnel Boring Machine (TBM) manufacturing facility. This strategic expansion is a critical step in localizing advanced tunneling technology, strengthening the 'Make in India' initiative.

Herrenknecht is expanding its Chennai operations by setting up a new manufacturing plant on a 12.4-acre site in Kannigaipaer in North Chennai, which was acquired for over ₹50 crore. The total investment for this expansion is planned to be approximately ₹250 crore (around EUR 28 million) and is expected to create an estimated 400 new jobs.

The new facility will produce large-diameter TBMs, including those up to 15.62 meters in diameter. The company already has an existing assembly facility in Chennai, established in 2007, where it currently manufactures 10-12 metro-sized TBMs annually with a localization rate of around 70% of components sourced locally. The expanded capacity will significantly enhance its ability to meet the burgeoning demand from major Indian infrastructure projects.

The TBMs manufactured at the expanded Chennai plant will be vital for high-profile underground projects across India. A prime example is the Mumbai Coastal Road Project North – Versova-Dahisar Link Road (VDLR).

-

VDLR Requirement: Herrenknecht is contracted to supply the largest TBMs in India for this project—two Mixshields, each with an immense diameter of 15.62 meters.

-

Project Scope: The VDLR is the second phase of the Mumbai Coastal Road Project, spanning 22.93 kilometers. The two parallel underground tunneling packages (C & D) will each extend 3.1 kilometers in length, connecting Versova and Dahisar. These tunnels, with an inner diameter of 14.7 meters, will carry six lanes (three in each tunnel).

-

Impact: The completed Versova-Dahisar extension is projected to reduce travel time by approximately 70% for millions of commuters, significantly easing congestion on arterial routes like the Western Express Highway.

This substantial investment underscores a major commitment to India's infrastructure growth and marks a significant step in Indo-German industrial collaboration.

-

Supply Chain Resilience: The decision to establish a large-scale manufacturing unit in India follows previous instances where export delays from Herrenknecht’s Chinese factories (reportedly due to political tensions and customs blocks) disrupted key Indian infrastructure projects. This localization will enhance supply chain efficiency, reduce the reliance on imports from other countries (including China), and mitigate geopolitical risks.

-

Technological Advancement: By producing advanced, large-diameter TBMs locally, the facility will promote cutting-edge tunneling technology and expertise within India, a market poised for massive underground construction, with tunneling projects worth over ₹3 lakh crore planned for the coming decade. India is currently ranked the second-largest TBM market in the world.

This expansion solidifies Herrenknecht's role as a complete solution provider in India, reinforcing its support for the country's ambitious urban development and sustainable mobility goals.