Jakson wins ₹163.7-crore E&M Works Contract for Corridor 4 of Chennai Metro Phase 2 Project

Jakson wins ₹163.7-crore E&M Works Contract for Corridor 4 of Chennai Metro Phase 2 Project Titagarh Rail Systems roll out First ‘Made in India’ Driverless Train for Ahmedabad Metro Phase 2

Titagarh Rail Systems roll out First ‘Made in India’ Driverless Train for Ahmedabad Metro Phase 2 Aarvee Engineering bags DPR Consultancy Contract for 59.6-km Bengaluru–Tumakuru Metro Extension

Aarvee Engineering bags DPR Consultancy Contract for 59.6-km Bengaluru–Tumakuru Metro Extension First priority corridor of Bhopal Metro inaugurated, India gets 20th city with modern MRTS network

First priority corridor of Bhopal Metro inaugurated, India gets 20th city with modern MRTS network SCC–MIRAL JV bags ₹118.6 crore contract for Multimodal Integration at Bullet Train Stations

SCC–MIRAL JV bags ₹118.6 crore contract for Multimodal Integration at Bullet Train Stations VinSpeed and Siemens Mobility join hands to develop Vietnam’s High-Speed Rail Network

VinSpeed and Siemens Mobility join hands to develop Vietnam’s High-Speed Rail Network Titagarh Rail Systems Bags ₹273.24-Crore Rolling Stock Contract from Indian Railways

Titagarh Rail Systems Bags ₹273.24-Crore Rolling Stock Contract from Indian Railways Metro Rail Transit Line (MRT-7): A New Way Forward for the North

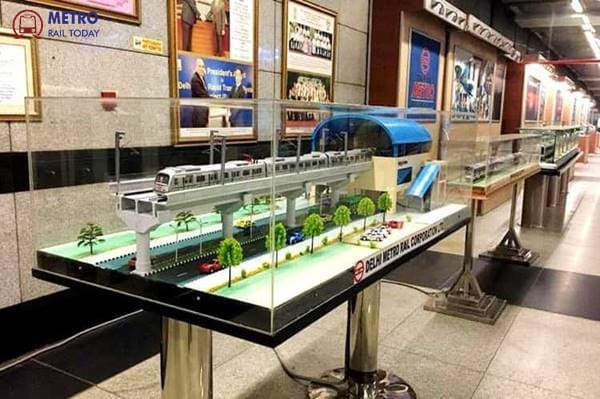

Metro Rail Transit Line (MRT-7): A New Way Forward for the North Delhi Metro inaugurates New State-of-the-Art Museum at Supreme Court Metro Station

Delhi Metro inaugurates New State-of-the-Art Museum at Supreme Court Metro Station Knorr-Bremse unviels plan to invest ₹1,907 Crore in New Rail Manufacturing Facility in Chennai

Knorr-Bremse unviels plan to invest ₹1,907 Crore in New Rail Manufacturing Facility in Chennai

Bangalore Metro Pink Line faces delays over Rolling Stock shortage

Bengaluru, India (Metro Rail Today): Bangalore Metro’s much-awaited Pink Line is headed for yet another delay — this time not due to construction, but because of an acute shortage of trains. While the 7.5-km elevated section between Kalena Agrahara and Tavarekere is structurally complete, trial runs remain on hold as no prototype rakes are available for testing.

The Bharat Earth Movers Limited (BEML), headquartered in Bengaluru, was slated to deliver the prototype metro train by June 2025, but production has been delayed. Testing of the prototype itself may now take an additional six months, pushing the operational timeline further into 2026.

At the heart of Bengaluru Metro’s delay lies a deeper structural problem — India’s dependence on imported components and the limited capacity of domestic manufacturing.

The crisis traces back to 2019, when the contract for the Yellow Line’s rolling stock was awarded to Chinese company CRRC. As per the ‘Make in India’ clause, CRRC was required to set up a local manufacturing facility — a task that became nearly impossible amid escalating geopolitical tensions and restrictions on Chinese firms.

After prolonged delays, CRRC entered into a joint venture with Titagarh Rail Systems, a leading Indian manufacturer based in Kolkata, to assemble metro coaches domestically. While this revived production, years of lost time have severely impacted Bengaluru Metro Rail Corporation Limited’s (BMRCL) expansion schedule.

Even BEML, which holds a ₹3,177 crore contract to supply 53 driverless trainsets for Bengaluru Metro’s Blue and Pink Lines, has hit roadblocks. Delays in the import of key components — such as gearboxes, motor wheel sets, and current collection devices — have slowed production schedules.

Further compounding the issue is the lack of domestic testing infrastructure for essential safety procedures, including bogie fatigue tests and car body squeeze tests, which are currently carried out abroad.

This mismatch between civil completion and rolling stock readiness has created a ripple effect across the city’s metro corridors, stalling progress and dampening commuter expectations.

Bengaluru is not alone. Metro systems in Mumbai, Chennai, Kolkata, and Pune are also grappling with train frequency shortages caused by slow rolling stock procurement, delayed imports, and limited supplier capacity.

India’s rapid urban transit expansion — with over 900 km of metro lines operational and another 1,000 km under construction — is straining the nation’s small pool of certified component manufacturers and testing facilities.

Experts warn that without strategic investment in rolling stock manufacturing ecosystems, such delays may continue to plague upcoming metro projects.

While the situation presents a challenge, it also offers a unique opportunity for Karnataka to position itself as India’s metro manufacturing hub.

Home to BEML, the country’s largest domestic supplier of metro coaches, Karnataka is well-placed to attract private sector investments in the production of ancillary components — such as bogies, braking systems, door mechanisms, and traction equipment — that are currently imported.

Industry experts suggest that the state government can facilitate dedicated industrial clusters around BEML’s Kolar Gold Fields (KGF) unit, offer targeted incentives, and promote vocational training programs to create a skilled workforce for the rail sector.

As metro systems expand into Tier-2 cities like Mysuru, Hubballi-Dharwad, and Mangaluru, the demand for rolling stock and subsystems will surge — creating a multi-billion-rupee opportunity for the state’s manufacturing ecosystem.

“The delay in Bengaluru Metro’s Pink Line underscores the urgent need for India to build self-reliant manufacturing capabilities in the metro and rolling stock segment,” said Mrs. Mamta Shah, MD & CEO of Urban Infra Group. “With the right policy support, Karnataka can transform this challenge into an opportunity and become the country’s epicenter for advanced metro manufacturing — driving both economic growth and technological innovation.”

As BMRCL works to synchronize its infrastructure readiness with train availability, stakeholders across India’s metro ecosystem are calling for greater synergy between policymakers, manufacturers, and testing agencies.

The future of India’s metro expansion depends not just on concrete and steel, but on how effectively the nation strengthens its rail manufacturing backbone — ensuring that cities like Bengaluru never again have to wait for trains on completed tracks.