Jakson wins ₹163.7-crore E&M Works Contract for Corridor 4 of Chennai Metro Phase 2 Project

Jakson wins ₹163.7-crore E&M Works Contract for Corridor 4 of Chennai Metro Phase 2 Project Titagarh Rail Systems roll out First ‘Made in India’ Driverless Train for Ahmedabad Metro Phase 2

Titagarh Rail Systems roll out First ‘Made in India’ Driverless Train for Ahmedabad Metro Phase 2 Aarvee Engineering bags DPR Consultancy Contract for 59.6-km Bengaluru–Tumakuru Metro Extension

Aarvee Engineering bags DPR Consultancy Contract for 59.6-km Bengaluru–Tumakuru Metro Extension First priority corridor of Bhopal Metro inaugurated, India gets 20th city with modern MRTS network

First priority corridor of Bhopal Metro inaugurated, India gets 20th city with modern MRTS network SCC–MIRAL JV bags ₹118.6 crore contract for Multimodal Integration at Bullet Train Stations

SCC–MIRAL JV bags ₹118.6 crore contract for Multimodal Integration at Bullet Train Stations VinSpeed and Siemens Mobility join hands to develop Vietnam’s High-Speed Rail Network

VinSpeed and Siemens Mobility join hands to develop Vietnam’s High-Speed Rail Network Titagarh Rail Systems Bags ₹273.24-Crore Rolling Stock Contract from Indian Railways

Titagarh Rail Systems Bags ₹273.24-Crore Rolling Stock Contract from Indian Railways Metro Rail Transit Line (MRT-7): A New Way Forward for the North

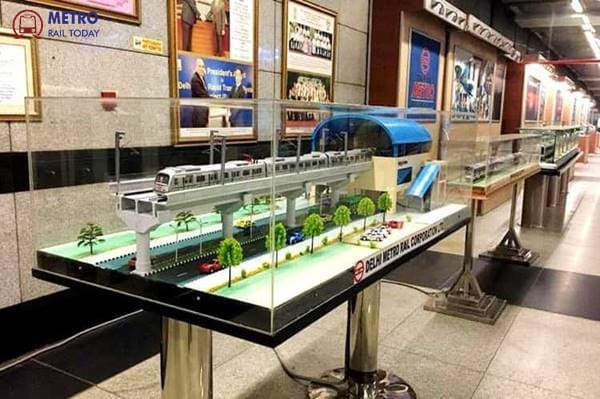

Metro Rail Transit Line (MRT-7): A New Way Forward for the North Delhi Metro inaugurates New State-of-the-Art Museum at Supreme Court Metro Station

Delhi Metro inaugurates New State-of-the-Art Museum at Supreme Court Metro Station Knorr-Bremse unviels plan to invest ₹1,907 Crore in New Rail Manufacturing Facility in Chennai

Knorr-Bremse unviels plan to invest ₹1,907 Crore in New Rail Manufacturing Facility in Chennai

Titagarh Rail Systems roll out First ‘Made in India’ Driverless Train for Ahmedabad Metro Phase 2

Ahmedabad, India (Metro Rail Today): In a major boost to India’s indigenous rail manufacturing capabilities, Gujarat Chief Minister Shri Bhupendra Patel on Saturday inaugurated the first ‘Made in India’ driverless Metro trainset for Ahmedabad Metro at Titagarh Rail Systems Limited’s Passenger Rail Systems facility in Uttarpara, West Bengal.

Calling it a landmark moment for India’s urban mobility sector, the Chief Minister said the project gives strong momentum to the ‘Make in India’ and ‘Aatmanirbhar Bharat’ initiatives, while reinforcing Gujarat’s vision for fast, sustainable public transport systems.

The newly unveiled metro trainset will be delivered to Ahmedabad Metro after completion of final testing and statutory certification in the coming days. The remaining nine trainsets will be supplied in phases over the next five to six months.

Gujarat Metro Rail Corporation Limited (GMRCL) has placed an order for 10 driverless metro trains with Kolkata-based Titagarh Rail Systems Limited to meet the additional rolling stock requirement arising from the expansion of Ahmedabad Metro Phase-2.

According to an official government statement, the new trains will support operations on an additional 21 km of Phase-2 corridors, with the remaining sections scheduled to become operational soon.

Growing Ridership and Network Expansion

At present, Ahmedabad Metro carries over 1.6 lakh passengers daily, with ridership growing at a robust 30–40 percent annually. Chief Minister Bhupendra Patel also stated that metro rail services will be extended to Surat in the coming phase, further strengthening Gujarat’s urban transit network.

The inauguration ceremony was attended by several senior officials, including Shri Hasmukh Adia, Principal Advisor to the Chief Minister and Shri S. S. Rathod, Advisor to the Chief Minister and Managing Director, GMRCL.

Addressing the gathering, the Chief Minister highlighted the transformation of India’s metro rail landscape, noting that under the Prime Minister’s leadership, metro networks have expanded from 248 km to over 1,013 km, fundamentally reshaping urban mobility across the country.

Manufacturing Excellence and Indigenous Content

The trainsets have been designed and manufactured at Titagarh’s state-of-the-art Uttarpara facility with a local content of 70–75 percent by value, underscoring India’s growing self-reliance in advanced rail technologies.

Key Manufacturing Highlights:

-

Train type: Fully driverless metro trainset

-

Carbody: Stainless steel – lightweight, corrosion-resistant, and durable

-

Manufacturing location: Uttarpara, West Bengal

Speaking on the occasion, Mr. Umesh Chowdhary, Vice Chairman & Managing Director, Titagarh Rail Systems Limited, said: “It is a matter of great honour for us to deliver India’s first Made-in-India driverless metro trainset for Ahmedabad. This milestone reflects our commitment to making India a global hub for railway manufacturing through engineering excellence, disciplined execution, and innovation.”

Ahmedabad Metro Phase-2 Network Details

The new trainsets will serve the Ahmedabad Metro Phase-2 network, covering two major corridors:

| Corridor | Route | Length |

|---|---|---|

| Yellow Line | Narendra Modi Stadium – Mahatma Mandir, Gandhinagar | 23.80 km |

| Violet Line | GNLU – PDEU – GIFT City | 5.40 km |

| Total | Elevated network across 22 stations | 28.26 km |

Advanced Technology and Passenger-Centric Design

The driverless metro trains are equipped with an advanced Train Control and Management System (TCMS) enabling unattended train operations (UTO). Designed with a strong focus on safety, comfort, and inclusivity, the trains feature:

-

Dedicated spaces for Persons with Reduced Mobility (PRM)

-

Ergonomically designed interiors

-

Energy-efficient systems enabled by lightweight stainless steel carbodies

Adding a distinctive local identity, the interiors incorporate a Garba-inspired theme, celebrating Ahmedabad’s cultural heritage while offering a modern commuter experience.

Future Expansion and High-Speed Rail Ambitions

During his visit to the facility, CM Patel also reviewed Titagarh’s manufacturing capabilities for Vande Bharat trains and appreciated the scale and speed of execution. The company outlined its future roadmap, which includes expanding capabilities for high-speed train manufacturing, positioning Titagarh as a global rail manufacturing player.

Commenting on the development, Mrs. Mamta Shah, MD & CEO, Urban Infra Group, said: “The rollout of India’s first indigenously manufactured driverless metro train is a defining moment for the country’s rail manufacturing ecosystem. Projects like Ahmedabad Metro demonstrate how ‘Make in India’ is translating into technologically advanced, globally competitive solutions that will shape the future of urban mobility.”

The inauguration of the Made-in-India driverless metro train reinforces Titagarh Rail Systems’ growing role in India’s rail modernisation journey and aligns closely with the national vision of Viksit Bharat, delivering sustainable, safe, and future-ready urban transport solutions.