Hitachi Rail awarded €481.6 Million Rolling Stock & System Contract for Turin Metro Line 2

Hitachi Rail awarded €481.6 Million Rolling Stock & System Contract for Turin Metro Line 2 Italian State Railways acquires Titagarh Firema from Titagarh Rail Systems Limited

Italian State Railways acquires Titagarh Firema from Titagarh Rail Systems Limited Railway Ministry to bear ₹90,000 Crore Cost Escalation for Mumbai–Ahmedabad Bullet Train Project

Railway Ministry to bear ₹90,000 Crore Cost Escalation for Mumbai–Ahmedabad Bullet Train Project CMRL achieves second Tunnel Breakthrough at Thirumayilai for Chennai Metro Phase 2 Corridor 4

CMRL achieves second Tunnel Breakthrough at Thirumayilai for Chennai Metro Phase 2 Corridor 4 NHSRCL invites Single Tender from BEML for Bullet Train Rolling Stock Package

NHSRCL invites Single Tender from BEML for Bullet Train Rolling Stock Package Railway Minister reviews progress of Ahmedabad–Dholera Semi High-Speed Rail Project

Railway Minister reviews progress of Ahmedabad–Dholera Semi High-Speed Rail Project National Planning Group reviews key Rail & Metro projects under PM GatiShakti

National Planning Group reviews key Rail & Metro projects under PM GatiShakti CMRS approves Driverless Metro Operations on first stretch of Chennai Metro Phase 2 Corridor 4

CMRS approves Driverless Metro Operations on first stretch of Chennai Metro Phase 2 Corridor 4 J Kumar Infraprojects completes Final Tunnel Breakthrough for Surat Metro Phase 1 Project

J Kumar Infraprojects completes Final Tunnel Breakthrough for Surat Metro Phase 1 Project Apurvakriti Infrastructure awarded Ballastless Track Contract for Pune Metro Reach-1 Extension

Apurvakriti Infrastructure awarded Ballastless Track Contract for Pune Metro Reach-1 Extension

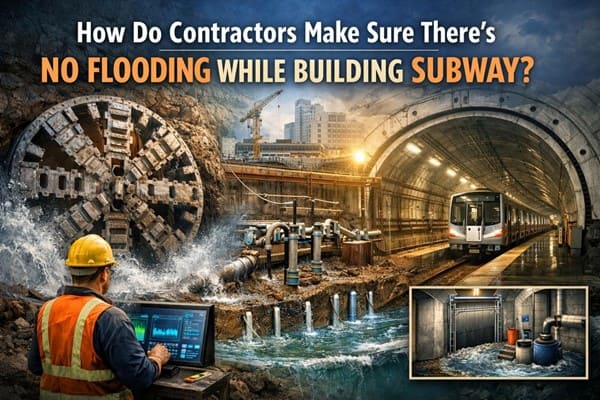

How Do Contractors Make Sure There’s No Flooding While Building Subways?

Subway construction is one of the most complex engineering tasks in modern infrastructure development. Unlike surface-level projects, subways are built deep underground, often below water tables, rivers, or densely populated urban areas. One of the biggest risks contractors face during subway construction is flooding. A single failure in water control can delay projects, increase costs, or even cause catastrophic structural damage.

So how do contractors make sure there’s no flooding while building subways? The answer lies in a combination of advanced engineering, geotechnical science, specialized equipment, and continuous monitoring. This article explores the proven methods contractors use to keep subway construction dry, safe, and structurally sound.

On the other hand, if you are on the hunt for a Tongits na baraha, be sure to visit GameZone.

Understanding the Flooding Risks in Subway Construction

Before construction even begins, engineers must assess the flooding risks unique to the project location. These risks include:

-

High groundwater levels

-

Proximity to rivers, lakes, or coastlines

-

Seasonal heavy rainfall or typhoons

-

Soft or porous soil types

-

Aging underground utilities or drainage systems

Urban subways are often built below the natural water table, meaning water pressure is constantly pushing inward. Without proper controls, groundwater can seep into tunnels, shafts, and stations.

Detailed Geotechnical Surveys and Soil Testing

Flood prevention starts long before excavation. Contractors conduct extensive geotechnical investigations to understand underground conditions.

These studies include:

-

Borehole drilling to analyze soil layers

-

Groundwater level measurements

-

Soil permeability tests

-

Seismic and hydrogeological analysis

By understanding how water moves through the soil, engineers can design tunnel linings, waterproofing systems, and excavation methods that resist water infiltration.

Tunnel Boring Machines (TBMs) With Pressure Control

Modern subway systems are typically built using Tunnel Boring Machines (TBMs), which play a crucial role in flood prevention.

There are specialized TBMs designed specifically for wet conditions:

Earth Pressure Balance (EPB) TBMs

These machines balance soil and water pressure at the tunnel face, preventing groundwater from rushing in during excavation.

Slurry Shield TBMs

Used in extremely wet or sandy ground, slurry TBMs use pressurized liquid to stabilize the tunnel face and block water intrusion.

By maintaining constant pressure, TBMs act as a moving barrier against flooding while excavation progresses.

Groundwater Control and Dewatering Systems

In areas with high groundwater levels, contractors rely on active water management techniques.

Dewatering Wells

Pumps are installed around the construction site to temporarily lower the groundwater table. This reduces water pressure on tunnels and excavation zones.

Wellpoint Systems

A network of small-diameter wells connected to vacuum pumps removes shallow groundwater, especially useful for station boxes and access shafts.

Recharge Systems

To prevent surrounding buildings from settling, removed groundwater is sometimes re-injected into nearby soil at controlled rates.

Dewatering is carefully monitored to avoid environmental damage or structural movement in nearby buildings.

Waterproof Tunnel Linings and Sealing Systems

Permanent flood protection comes from advanced waterproofing technologies built directly into the subway structure.

Segmental Concrete Linings

Precast concrete segments are installed behind the TBM to form the tunnel walls. These segments include:

-

Rubber gaskets

-

Precision-fit joints

-

Water-resistant concrete mixes

When assembled, they create a watertight ring that blocks groundwater entry.

Injection Grouting

If small leaks appear, contractors inject chemical or cement-based grout into cracks and soil voids to seal water pathways.

Ground Freezing for Extreme Conditions

In particularly challenging environments, artificial ground freezing is used to stop water flow.

This method involves:

-

Installing freeze pipes around the excavation area

-

Circulating super-cooled brine or liquid nitrogen

-

Freezing soil and groundwater into a solid mass

Frozen ground acts as a temporary waterproof wall, allowing safe excavation for tunnels, cross-passages, or station connections.

Cut-and-Cover Drainage and Waterproofing

For shallow subway sections built using the cut-and-cover method, flood prevention relies heavily on structural waterproofing.

Key measures include:

-

Waterproof membranes beneath and around station boxes

-

Drainage layers to redirect water away from structures

-

Sump pits and permanent pumping systems

These systems ensure rainwater and groundwater are safely managed even after the subway opens.

Flood Gates, Sumps, and Permanent Pumping Systems

Once the subway is operational, long-term flood protection becomes critical.

Pumping Stations

Subway systems include permanent pumps that automatically remove water from low points, tunnels, and stations.

Flood Barriers and Gates

At entrances, ventilation shafts, and tunnel portals, flood gates can be deployed during storms or emergencies to block surface water from entering.

Redundant Systems

Critical pumps and gates are backed up with:

-

Emergency power supplies

-

Secondary pump units

-

Remote monitoring

This redundancy ensures protection even during power outages or extreme weather events.

Real-Time Monitoring and Smart Sensors

Modern subway construction uses digital monitoring to detect water issues early.

Sensors track:

-

Groundwater pressure

-

Tunnel deformation

-

Water seepage rates

-

Soil movement

If abnormal readings occur, construction teams can respond immediately before flooding becomes a serious problem.

Emergency Preparedness and Risk Management

Even with advanced systems in place, contractors prepare for worst-case scenarios.

Emergency plans include:

-

Rapid sealing materials

-

Backup pumps and generators

-

Predefined evacuation procedures

-

24/7 monitoring teams

These measures reduce downtime and protect workers, equipment, and surrounding infrastructure.

Why Flood Prevention Is Critical to Subway Safety

Preventing flooding during subway construction is not just about keeping the site dry. It directly affects:

-

Structural integrity of tunnels and stations

-

Safety of construction workers

-

Stability of nearby buildings and roads

-

Long-term durability of the subway system

A properly waterproofed subway can operate safely for decades with minimal maintenance.

Conclusion

So, how do contractors make sure there’s no flooding while building subways? They rely on a layered approach combining geotechnical science, advanced machinery, groundwater control, waterproof materials, and real-time monitoring. From pressure-balanced tunnel boring machines to permanent pumping systems, every stage of subway construction is designed with water control in mind.

As cities expand and climate risks increase, these flood-prevention strategies are becoming even more critical. Rising sea levels, heavier rainfall, and aging urban drainage systems mean modern subways must be built to withstand extreme conditions from day one. Through careful planning, advanced engineering, and continuous maintenance, contractors ensure underground transit systems remain resilient, reliable, and safe for millions of commuters for decades to come.